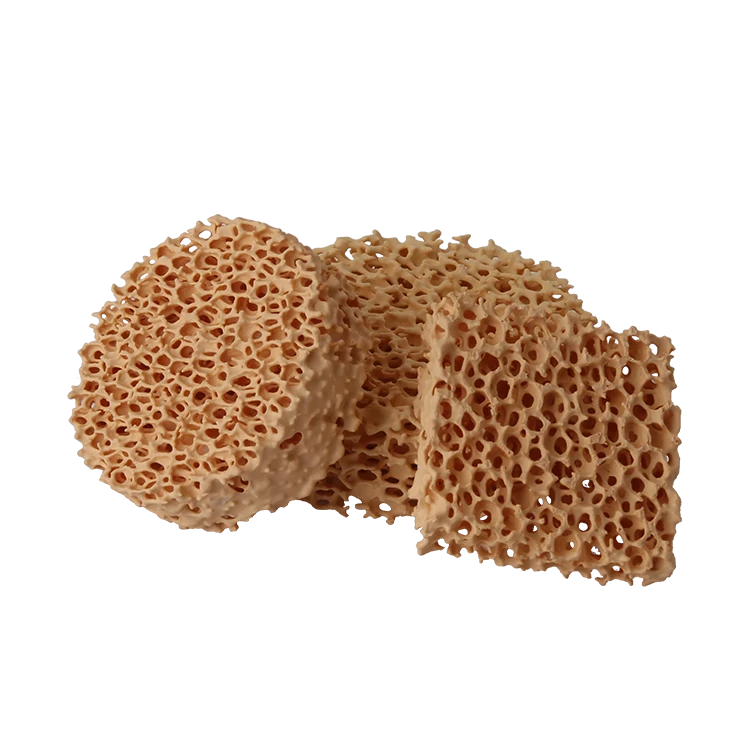

In the field of high-end casting manufacturing, the purity of the molten metal directly determines the final performance of the product. As the most advanced filtering technology at present, zirconia foam ceramic filters have become an indispensable core component of precision casting with their unique material properties. This porous ceramic product seems simple, but it contains the exquisite combination of material science and fluid dynamics, and is a process guarantee that is difficult to replace with ordinary filter materials.

Material stability under extreme environments

The most significant advantage of zirconia is its amazing high-temperature stability. When ordinary ceramic filters soften and deform in a molten steel environment above 1600°C, zirconia still maintains a complete crystal structure. This innate heat-resistant talent enables it to withstand the most severe thermal shock test during the casting process. What is even more rare is that under continuous high temperature environment, zirconia will not react with active metal elements, ensuring the chemical purity of the filtration process.

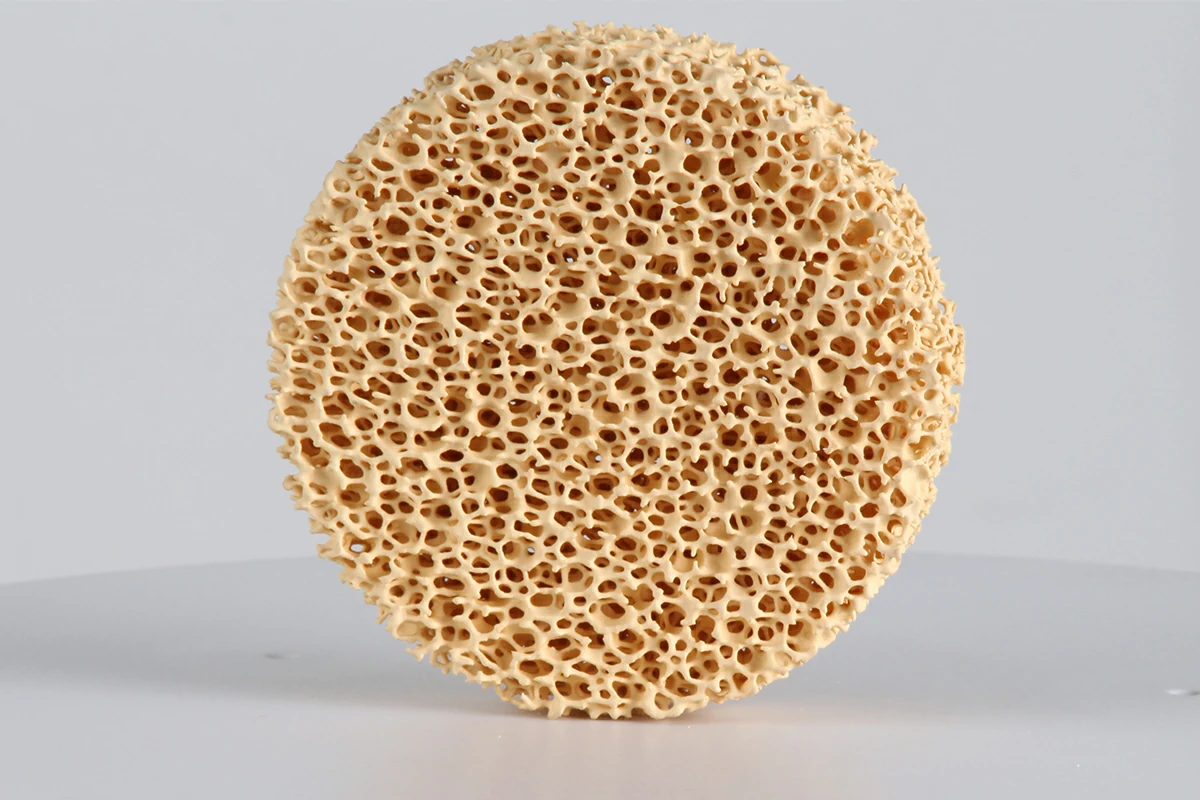

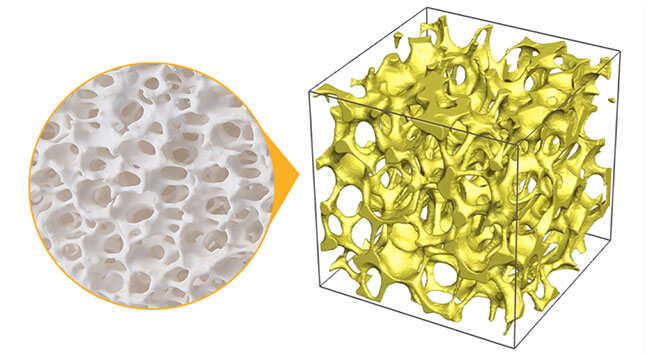

Precision filtration mechanism of three-dimensional structure

The three-dimensional mesh structure inside the zirconia filter is a molecular-level trap designed by a special process. When the metal melt flows through these intricate microporous channels, the inclusions undergo a multi-stage purification process: large particles are directly intercepted, medium-sized impurities collide and deposit due to fluid deflection, and the finest suspended matter is strongly adsorbed by the skeleton surface. This gradient filtration effect is something that ordinary straight-through filters can never achieve.

Improvement of microstructure

The solidification behavior of the metal melt purified by the zirconia filter will undergo subtle but important changes. A purer melt means more uniform nucleation conditions, and ultimately an ideal structure with fine grains and uniform phase distribution is obtained. This optimization of the microstructure directly translates into an overall improvement in the strength, toughness and fatigue life of the casting.

Guarantee of quality consistency

Zirconium oxide filters maintain stable filtration efficiency throughout their service life, without the performance degradation problems common to ordinary materials. This reliability ensures that each batch of castings can meet strict quality standards, and is particularly suitable for fields such as aerospace and energy equipment that require extremely high consistency.

The inevitable choice of technological development

As castings develop towards thin-walled, large-scale, and precise directions, traditional filtration technology has approached its performance limit. The combined advantages of zirconia materials in thermal shock resistance, chemical inertness and structural stability make it the best choice for new challenges. This technological generation gap is particularly evident when casting high-end materials such as ultra-high strength steel and heat-resistant alloys.

From the nature of the material to the structural design, zirconia foam ceramic filters represent the highest level of current casting filtration technology. It is not only a simple purification tool, but also a key medium connecting material science and manufacturing processes. In the field of high-end casting that pursues extreme performance, choosing zirconia filters is no longer a cost issue, but an inevitable requirement for quality assurance. With the continuous development of new material technology, the potential of this important component will continue to be released.