Introduction

Ceramics are widely used in industrial and medical applications due to their excellent properties. Among them, alumina and zirconia ceramics are two of the most important materials. Although both are advanced ceramics, they have distinct differences.

What is Alumina Ceramic?

Alumina ceramic is a ceramic material primarily composed of aluminum oxide. It is one of the most commonly used technical ceramics. It offers good mechanical strength, high hardness, and excellent electrical insulation. Alumina ceramics are also resistant to high temperatures and chemical corrosion. Due to their affordability and reliability, they are widely used in various industries.

What is Zirconia Ceramic?

Zirconia ceramic is a ceramic material mainly made of zirconium dioxide. It is known for its exceptional toughness and strength compared to other ceramics. Zirconia also has high wear resistance and good thermal insulation properties. Additionally, it exhibits excellent biocompatibility, making it suitable for medical implants.

Comparison of Mechanical Properties

Alumina ceramic has high hardness but is relatively brittle. It can withstand heavy loads but may crack under impact. Zirconia ceramic, on the other hand, has superior fracture toughness. It resists crack propagation better than alumina. This makes zirconia more suitable for applications requiring high durability.

Comparison of Thermal Properties

Alumina ceramic has good thermal stability and can withstand high temperatures. However, its thermal conductivity is higher than zirconia. Zirconia ceramic has lower thermal conductivity, making it a better thermal insulator. It also has higher resistance to thermal shock.

Comparison of Chemical Resistance

Both alumina and zirconia ceramics exhibit strong chemical resistance. Alumina is highly resistant to acids and alkalis. Zirconia also resists chemical corrosion but may degrade in certain extreme conditions. Overall, alumina is slightly more stable in harsh chemical environments.

Comparison of Electrical Properties

Alumina ceramic is an excellent electrical insulator. It is widely used in electronic components due to its high dielectric strength. Zirconia ceramic also has insulating properties but is less commonly used in electrical applications. Its primary advantages lie in mechanical and thermal performance.

Comparison of Biocompatibility

Zirconia ceramic is highly biocompatible, making it ideal for dental and medical implants. It does not trigger immune responses in the human body. Alumina ceramic is also biocompatible but less commonly used in medical applications compared to zirconia.

Applications of Alumina Ceramic

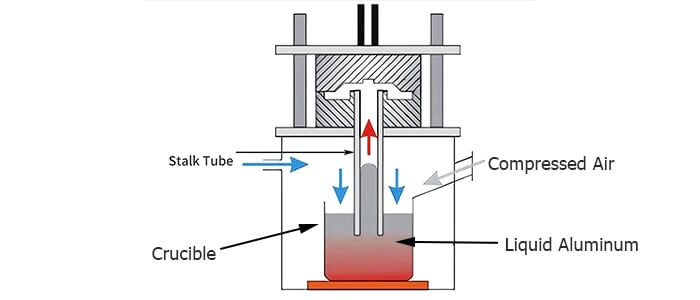

Alumina ceramic is used in electrical insulators, cutting tools, and wear-resistant components. It is also applied in chemical equipment and high-temperature furnaces. Its affordability makes it a popular choice for industrial uses.At the same time, it can also be made into filter sheets for filtering impurities in the foundry industry, etc.Alumina ceramic filter is a porous ceramic material with high-purity alumina as the main component. It is suitable for harsh environments such as chemical industry, water treatment and high-temperature gas filtration.

Applications of Zirconia

Ceramic Zirconia ceramic is commonly used in dental crowns, medical implants, and precision bearings. It is also found in high-performance cutting tools and aerospace components. Its high cost limits its use to specialized fields.It can also be made into filter discs for filtering molten steel and other casting fields. Zirconia ceramic filter discs are made of high-purity zirconium oxide, have better toughness and wear resistance, can withstand high temperatures of 1700 degrees Celsius, and are widely used in the casting field.

Conclusion

Both alumina and zirconia ceramics have unique advantages. Alumina is preferred for general industrial uses due to its affordability. Zirconia is chosen for high-performance and medical applications. Understanding their differences helps in selecting the right material for specific needs.