Introduction to Gating Systems

In sand casting, the gating system serves as the crucial pathway that guides molten metal from the pouring cup into the mold cavity. This network of channels performs multiple essential functions beyond simple metal transfer, acting as the circulatory system of the casting process. A properly designed gating system controls the speed, direction, and quality of metal flow while preventing common defects. The components work together to ensure complete mold filling, proper temperature distribution, and effective slag separation, making it fundamental to casting success.

Main Components and Their Functions

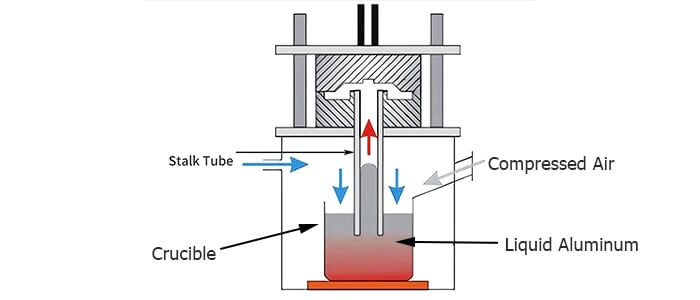

The standard gating system consists of several interconnected elements. The pouring basin receives the molten metal initially and helps stabilize the flow. The sprue, a vertical channel, then directs the metal downward with controlled velocity. Runners, the horizontal passages, distribute the metal to various sections of the mold. Gates, the final connectors to the mold cavity, regulate the entry speed to prevent turbulence. The system often includes additional features like ceramic filters for cleaning the metal and risers for feeding solidification shrinkage. Together, these components create a coordinated metal delivery network.

Design Principles and Considerations

Designing an effective gating system requires careful balancing of multiple factors. Hydraulic principles dictate that the system should maintain pressurized flow to prevent air aspiration while avoiding excessive velocity that causes erosion. The cross-sectional areas of different components follow calculated ratios to control metal velocity and ensure proper filling sequence. Thermal considerations include preventing premature cooling in thinner sections and managing heat distribution for directional solidification. The design must also accommodate the specific characteristics of the alloy being cast, accounting for its fluidity, solidification behavior, and oxidation tendency.

Common Types and Configurations

Gating systems vary significantly based on casting requirements and foundry practices. Top gating introduces metal from above the mold cavity, benefiting from gravitational force but risking turbulence. Bottom gating systems fill the mold upward for calmer flow but may develop thermal gradients. Parting line gating offers practical advantages in mold assembly, while stepped systems combine multiple approaches for complex castings. Specialized designs like whirl gates employ centrifugal action for slag separation. The selection depends on factors like casting size, section thickness, alloy type, and quality requirements, with each configuration presenting unique advantages and compromises.

Functional Requirements and Performance Criteria

A well-engineered gating system must satisfy several critical performance criteria. It should deliver clean, oxide-free metal to the mold cavity by effectively trapping and retaining impurities in the system. The design must establish proper thermal gradients to promote directional solidification toward the feeders. Flow characteristics should minimize turbulence to prevent gas entrapment and mold erosion while maintaining adequate velocity to avoid misruns.

The Vital Role in Casting Quality

The gating system represents far more than just passageways for metal – it’s a sophisticated metallurgical control device that significantly influences casting integrity and quality. Proper understanding and application of gating principles allow foundries to prevent defects at their source rather than compensating for them later. As casting technology advances with new materials and methods, the fundamentals of gating system design remain central to producing sound castings efficiently. The continuing development of simulation tools and smart foundry technologies promises further refinements in this critical aspect of metalcasting.