Basic Characteristics of Zirconia Filters

Zirconia filters are high-performance ceramic materials known for their excellent thermal resistance, chemical stability, and mechanical strength. In copper and copper alloy casting, zirconia filters can withstand the impact of high-temperature molten copper while maintaining structural integrity without failure due to thermal shock or chemical corrosion. Their fine porous structure effectively traps non-metallic inclusions , significantly improving the purity of the molten metal.

Common Defects in Copper Castings and the Role of Filtration

Copper castings are prone to defects such as porosity, inclusions, and shrinkage cavities during production, often caused by impurities or gases in the molten metal. Without effective filtration, these impurities can enter the mold with the molten metal, eventually forming defects inside or on the surface of the casting, affecting mechanical properties, electrical conductivity, and appearance. Zirconia filters reduce the likelihood of impurities entering the mold through physical interception and adsorption, thereby lowering the defect rate and improving overall quality.

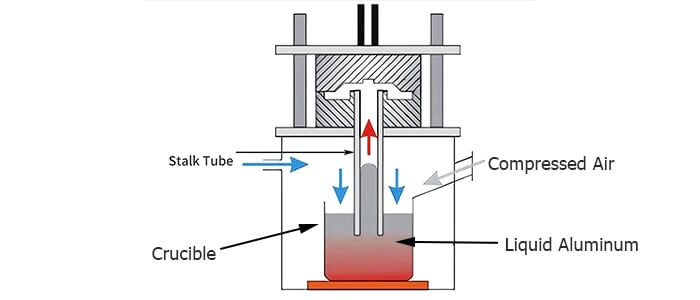

The Role of Zirconia Filters in Molten Copper Purification

Before copper pouring, molten metal often contains fine particles and slag, which can directly affect the density and uniformity of castings if not removed. Zirconia filters efficiently trap impurities of various sizes through their uniformly distributed microporous structure while avoiding flow restriction. Additionally, the inert nature of zirconia ensures no chemical reaction with molten copper, preventing new contamination and maintaining the chemical stability of the metal.

Impact of Filtration on Copper Casting Performance

The use of zirconia filters in casting significantly improves the mechanical and electrical properties of copper castings. The higher purity of filtered molten metal results in a more uniform internal structure, reducing stress concentration and crack susceptibility. High-purity copper castings also exhibit superior electrical and thermal conductivity, making them suitable for demanding applications in the electrical and electronics industries.

The Value and Future of Zirconia Filters

The application of zirconia filters in copper casting not only improves casting quality but also enhances production efficiency and reduces scrap rates. As copper alloys find broader use in high-tech industries, the demand for higher material purity continues to grow, ensuring the ongoing importance of zirconia filtration technology. Future advancements in materials science and process optimization may further enhance the efficiency of zirconia filters in more complex casting environments.