Introduction: The Unsung Hero of Metal Casting

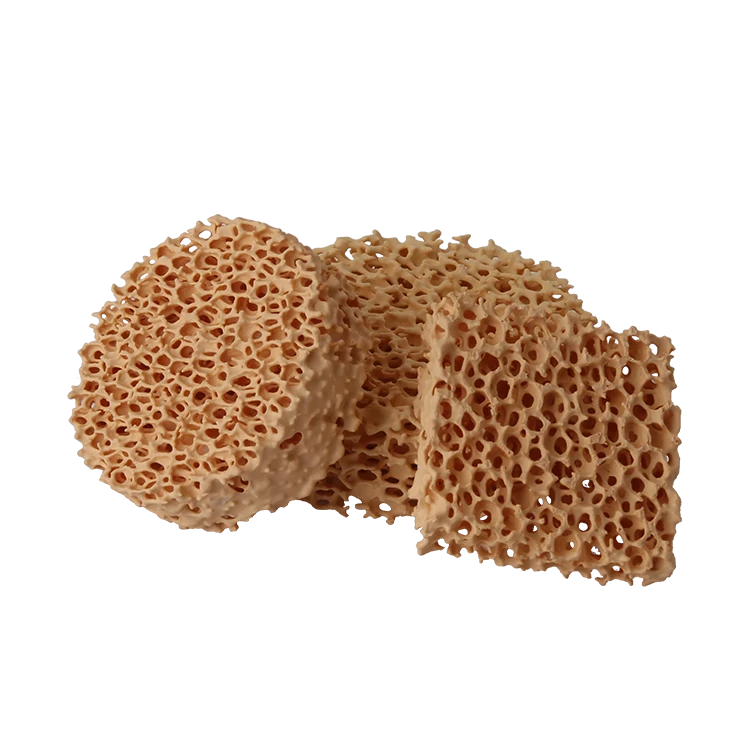

In the intricate world of metal casting, alumina ceramic foam filters operate as silent guardians of quality. These unassuming white ceramic blocks, often overlooked in production planning, play a pivotal role in determining the final integrity of cast components. While foundries frequently focus on adjusting melting parameters or modifying mold designs to address quality issues, the critical influence of filtration technology frequently remains underestimated.

Material Alchemy: The Making of a Superior Filter

The essence of alumina foam filters lies in their specialized material composition. High-purity aluminum oxide undergoes a transformative process where carefully controlled sintering creates a unique ceramic matrix. This isn’t simply about heating raw materials; it’s a precise dance of temperature and time that develops the material’s signature characteristics – the perfect balance of structural integrity and porous architecture.

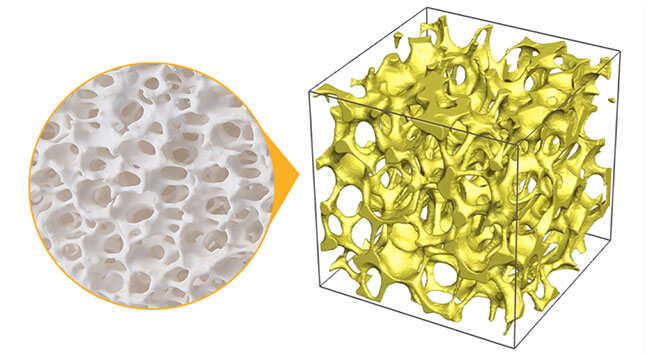

Architecture of Purity: Understanding the 3D Filtration Matrix

What appears as a simple porous block reveals extraordinary complexity under magnification. The filter’s internal structure resembles a microscopic labyrinth of interconnected ceramic struts, forming passageways that are neither random nor uniform. This intentional irregularity creates multiple filtration mechanisms operating simultaneously: surface skimming at entry points, turbulent deposition in mid-channels, and molecular attraction along the ceramic surfaces. The brilliance of this design lies in its ability to adapt its filtration approach based on impurity size and metal flow dynamics.

Thermal Warriors: Defying Extreme Casting Environments

When immersed in searing molten metal, ordinary materials falter – but alumina filters thrive. Their secret lies in atomic-level bonding that remains steadfast where others weaken. This thermal resilience combines with chemical inertness to create a filter that purifies without contaminating, resisting both the physical erosion of flowing metal and chemical reactions with aggressive alloying elements.

The Flow Whisperer: Hydraulics of Metal Filtration

Beyond particle capture, these filters perform subtle metalflow alchemy. Their porous networks transform chaotic turbulent streams into orderly laminar flows, a process critical for defect-free castings. This hydraulic regulation occurs through millions of microscopic interactions where the ceramic structure gently corrects the metal’s motion without abrupt resistance. The result is molten metal that fills molds evenly, minimizing gas entrapment and optimizing solidification patterns .

Silent Quality Control: The Filter’s Ripple Effect

The filter’s influence persists long after metal passes through its pores. By ensuring cleaner melts, it fundamentally alters solidification behavior. Nucleation sites increase dramatically, creating finer grain structures that enhance mechanical properties. This microstructural improvement translates to tangible benefits: castings with better surface finish, improved pressure tightness, and enhanced fatigue resistance. In premium applications like aerospace components, this level of quality control isn’t just beneficial – it’s mandatory.

Conclusion: Small Component, Monumental Impact

From automotive wheels to jet engine turbine blades, alumina ceramic foam filters quietly enable manufacturing excellence across industries. Their value proposition extends beyond immediate quality improvement to encompass energy savings through reduced scrap and longer tooling life. As casting technologies advance toward thinner walls and more complex geometries, these unassuming ceramic components will continue to play an indispensable role in turning molten metal into precision engineered components.