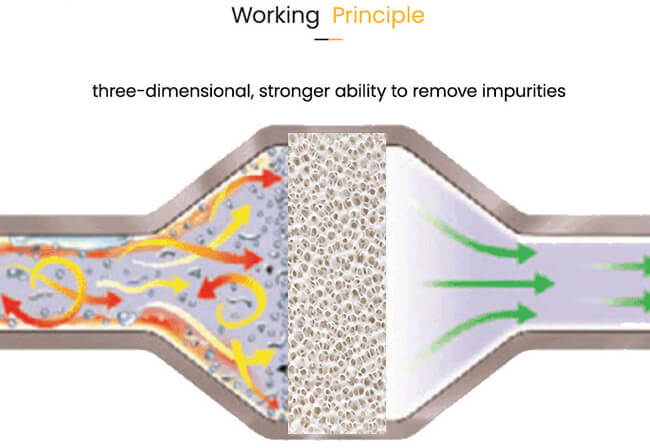

In the metal casting process, alumina foam ceramic filter acts as a purification barrier for molten metal. Its unique structural design and working principle determine the key performance of the filtration effect. This porous ceramic material has become an important process link to improve the quality of castings through the synergistic effect of physical interception and chemical stability. Understanding its structural characteristics and mechanism of action will help optimize the design and application of the filtration system.

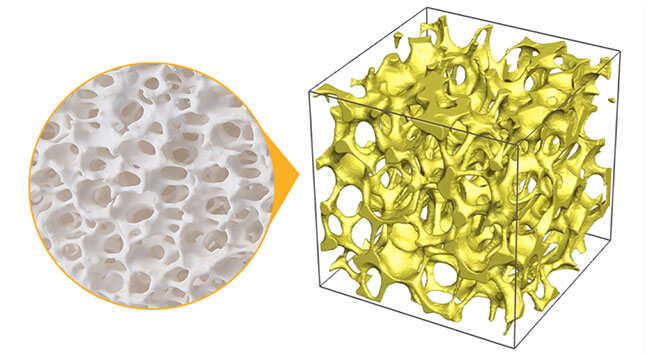

Composition of three-dimensional mesh structure

The core feature of alumina foam ceramic filter is its through-hole three-dimensional mesh pore structure. The structure is composed of a high-purity alumina ceramic skeleton, and a network of interconnected channels is formed through a special foaming process. This high porosity design not only ensures sufficient metal liquid passing capacity, but also provides sufficient impurity interception surface area.

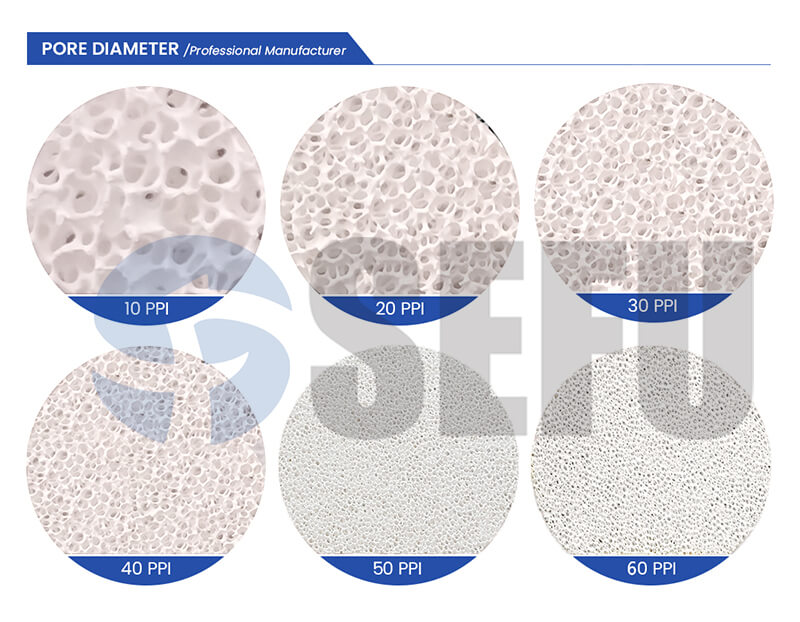

Determinants of filtration accuracy

The performance index PPI of the filter directly reflects the precision of the structure. When the PPI value increases, the average pore size decreases. This geometric change brings about a qualitative change in the filtration mechanism: the large-aperture structure mainly relies on inertial collision to intercept macro inclusions, while the micron-level pores capture fine particles through deep filtration effects.

High temperature stability and chemical inertness

The essential characteristics of alumina materials give the filter excellent environmental adaptability. Within the temperature range of aluminum liquid, the alumina phase maintains a stable crystal structure, avoiding pore deformation caused by sintering shrinkage. At the same time, the interfacial energy between alumina and molten aluminum is low, which can effectively prevent the metal liquid from infiltrating and corroding the skeleton. This chemical inertness ensures that no secondary pollution is introduced during the filtration process, which is an essential advantage over organic filter materials.

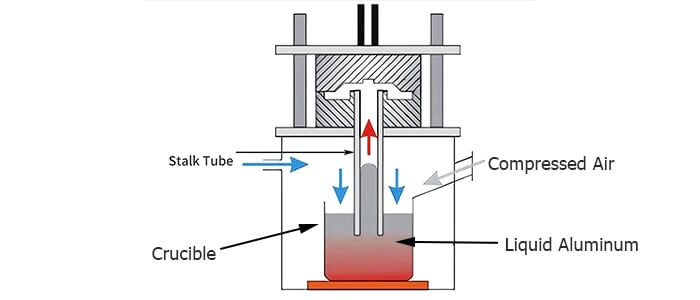

Flow field optimization and process adaptation

The structural design of the filter must take into account both the filtration effect and the metal fluidity. The ideal pore structure will cause moderate turbulence in the metal liquid, promote the separation of impurities, while maintaining an overall laminar state to avoid air entrainment. In the actual casting system, the installation position and support method of the filter directly affect the flow field distribution. Reasonable configuration can eliminate the metal liquid injection effect and achieve the best balance between the filtration process and the pouring speed.

Performance degradation and replacement timing

As the use time increases, the filter will experience a performance degradation process. The gradual blockage of the pores leads to an increase in the pressure difference and a prolonged metal liquid passage time; repeated thermal cycles may cause microcracks and form impurity bypass channels. These changes are slow but irreversible. When the filtration efficiency drops to a critical value, it needs to be replaced even if the physical structure is not damaged.

The alumina foam ceramic filter has developed a simple physical interception into a multi-mechanism coordinated precision purification system through a carefully designed microstructure. From raw material ratio to pore forming, from high-temperature sintering to application adaptation, each link reflects the deep integration of material science and casting technology. With the advancement of technology in the future, this material will continue to play an irreplaceable role in the casting field.