Introduction to Aluminum Oxide and Silicon Carbide

Aluminum oxide and silicon carbide are two widely used ceramic materials with distinct properties and applications. Both materials exhibit high hardness, thermal stability, and chemical resistance, making them suitable for demanding industrial environments. However, their differences in composition, structure, and performance characteristics lead to varied uses across multiple fields. Understanding the fundamental distinctions between aluminum oxide and silicon carbide is essential for selecting the appropriate material for specific applications.

Mechanical Properties and Hardness

Both aluminum oxide and silicon carbide are renowned for their hardness, but silicon carbide generally exhibits superior mechanical strength. Aluminum oxide is a hard and wear-resistant material, commonly used in abrasives and cutting tools. However, silicon carbide surpasses it in terms of hardness, ranking close to diamond on the Mohs scale. This extreme hardness makes silicon carbide ideal for applications requiring resistance to wear and deformation under high-stress conditions.

Thermal Conductivity and Heat Resistance

Thermal properties are a key differentiator between aluminum oxide and silicon carbide. Silicon carbide possesses significantly higher thermal conductivity, allowing it to dissipate heat efficiently. This characteristic makes it highly suitable for applications in high-temperature environments, such as in semiconductor devices and thermal management systems. Aluminum oxide, while still thermally stable, has lower thermal conductivity, which can limit its effectiveness in heat dissipation. However, its excellent electrical insulation properties make it a preferred choice for electrical and electronic components where thermal conduction is not the primary requirement.

Chemical Stability and Corrosion Resistance

Both materials exhibit strong resistance to chemical corrosion, but their performance varies depending on the environment. Aluminum oxide is highly inert and resistant to attack by acids and alkalis, making it suitable for use in chemically aggressive settings. Silicon carbide also demonstrates excellent chemical resistance, particularly in oxidizing atmospheres at high temperatures. However, it may be susceptible to degradation in strongly alkaline conditions.

Electrical Properties and Applications

The electrical characteristics of aluminum oxide and silicon carbide differ significantly, influencing their respective applications. Aluminum oxide is an excellent electrical insulator, widely used in substrates and insulating components for electronic devices. In contrast, silicon carbide exhibits semiconducting properties, making it valuable in high-power and high-frequency electronic applications. The ability of silicon carbide to operate at higher voltages and temperatures than traditional semiconductors like silicon has led to its adoption in advanced power electronics and electric vehicle technologies.

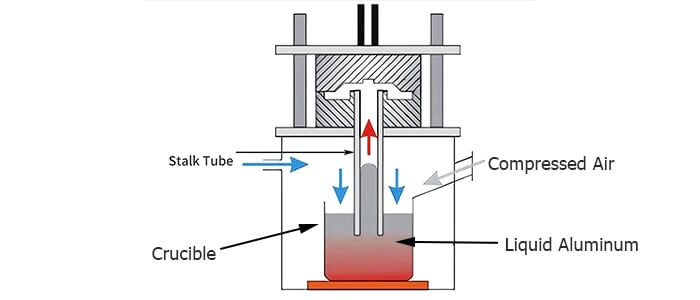

Comparison of Alumina and Silicon Carbide Ceramic Filters

Alumina and silicon carbide ceramic filters are critical materials in high-temperature filtration, each with distinct advantages. Alumina filters exhibit strong chemical inertness, performing exceptionally in neutral and mildly corrosive environments, and are cost-effective, making them ideal for molten metal purification and chemical filtration. In contrast, silicon carbide filters, with superior thermal conductivity, exceptional thermal shock resistance, and mechanical strength, excel in extreme conditions , highly corrosive or high-stress applications , though at a higher production cost. Additionally, SiC’s wear resistance far surpasses alumina, ensuring durability in abrasive environments. The choice depends on temperature, corrosion, mechanical demands, and cost considerations.

Conclusion: Selecting the Right Material

The choice between aluminum oxide and silicon carbide depends on the specific requirements of the intended application. Aluminum oxide offers a cost-effective solution with good mechanical and electrical insulation properties, suitable for a wide range of industrial uses. Silicon carbide, with its superior hardness, thermal conductivity, and high-temperature performance, is the material of choice for more demanding environments. Understanding the strengths and limitations of each material ensures optimal selection for engineering and technological applications.