What is Alumina Ceramic?

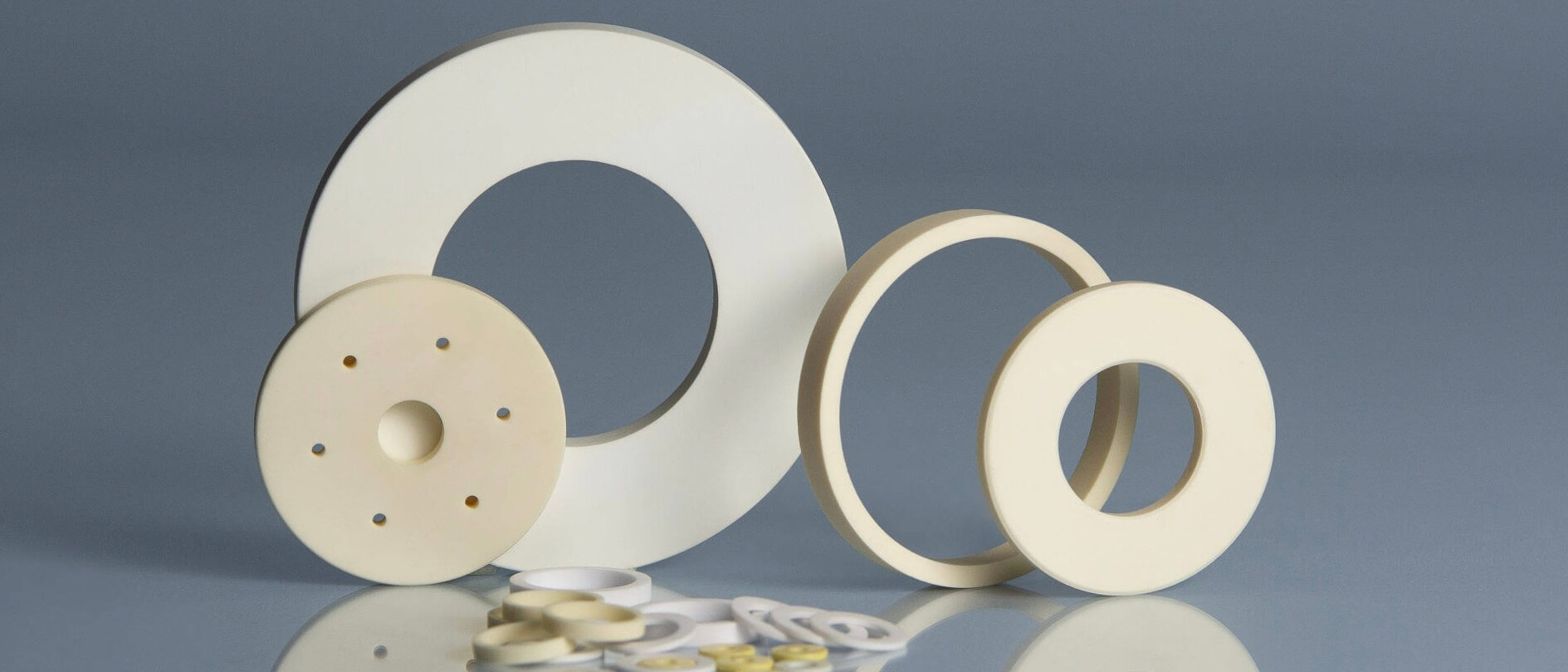

Alumina ceramic, chemically known as aluminum oxide (Al₂O₃), represents one of the most technologically significant advanced ceramics in modern industry. This engineered material is created through precise processing of purified aluminum oxide powders, which are carefully sintered at extreme temperatures to form a dense, polycrystalline structure. Unlike traditional ceramics derived from clay, alumina ceramics exhibit exceptional purity levels, typically ranging from 96% to 99.9% aluminum oxide content. The material’s distinctive white color and slightly translucent appearance in thin sections hint at its refined microstructure.

Is Alumina Ceramic Safe?

The safety profile of alumina ceramic makes it uniquely valuable across sensitive applications. As an inert, non-toxic material, it presents no chemical hazards during normal use, even in demanding environments. The ceramic’s thermal stability ensures it won’t decompose or release harmful substances when exposed to high temperatures that would cause many materials to degrade. Furthermore, its electrical insulation properties eliminate risks of current leakage or short circuits in electronic applications. The material’s biocompatibility has been thoroughly validated, allowing its use in medical implants and food processing equipment without concerns about adverse reactions or contamination.

What Are the Benefits of Alumina Ceramics?

The advantages of alumina ceramics stem from their unique combination of physical properties that outperform many conventional materials. Exceptional hardness, approaching that of sapphire (which shares the same chemical composition), grants remarkable wear resistance in mechanical applications. Its high melting point and thermal shock resistance enable performance in extreme temperature environments where metals would fail. The material’s electrical insulation capabilities remain stable across wide temperature ranges, while its dielectric strength surpasses most other ceramics. Chemically, alumina demonstrates outstanding resistance to strong acids and alkalis, along with superior biocompatibility that enables medical applications. Perhaps most significantly, these diverse properties coexist in a single material that can be precision-engineered into complex shapes.

What are the applications of alumina ceramics

The future development of alumina ceramics will focus on the dual breakthroughs of performance optimization and application expansion. T The integration of intelligent manufacturing technology will reshape its production methods, making precision and customized production possible. Driven by the concept of sustainable development, green manufacturing processes and recycling systems will be further improved. At the same time, interdisciplinary innovation is driving the evolution of alumina ceramics towards intelligence and multifunctionality, allowing its application boundaries in high-end industries, biomedicine, new energy and other fields to continue to expand. As a professional alumina ceramic manufacturer, SEFU has been deeply involved in the industry for many years, and its alumina filter and other products have shown excellent performance in many fields. We have always been committed to the innovative research and development of alumina ceramics, and provide customers with customized solutions with better performance and lower cost by continuously optimizing material formulas and manufacturing processes.

The Future of Alumina Ceramics

The future development of alumina ceramics will focus on the dual breakthroughs of performance optimization and application expansion. The new generation of alumina ceramics will make precision and customized production possible while maintaining excellent physical and chemical properties. Driven by the concept of sustainable development, green manufacturing processes and recycling systems will be further improved. At the same time, interdisciplinary innovation is driving the evolution of alumina ceramics towards intelligence and multifunctionality, allowing its application boundaries in high-end industry, biomedicine, new energy and other fields to continue to expand. This traditional advanced ceramic is radiating new vitality under the empowerment of science and technology, gradually transforming from a single structural material to a new generation of functional materials with integrated sensing, response and other intelligent characteristics.