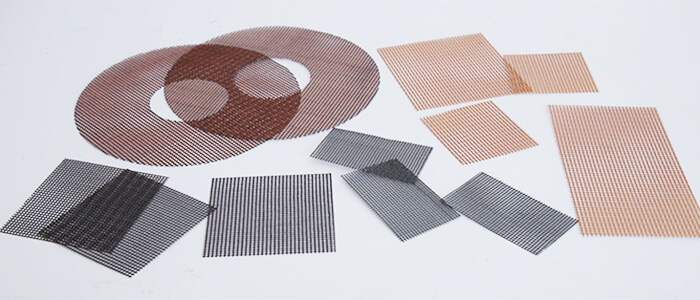

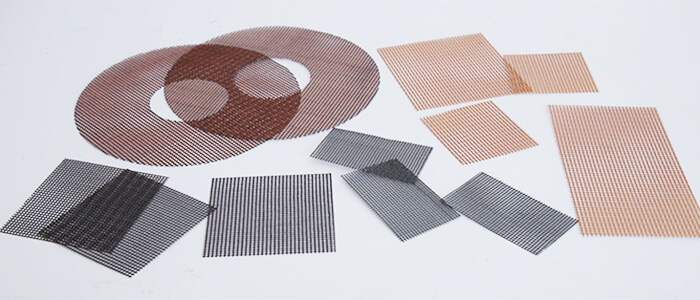

In the production process of aluminium castings, the purity of the molten metal directly determines the quality of the final product. As an invisible quality defense line, the fiberglass mesh filter for molten aluminium filtration is playing an irreplaceable role in high-end aluminium casting workshops around the world. This seemingly simple filter material is actually a precision product that integrates material science, fluid mechanics and casting technology. It can effectively intercept oxides, non-metallic inclusions and bubbles in the aluminium liquid and reduce the porosity of the casting.

Scientific basis for material selection

The fiberglass mesh filter used for molten aluminium filtration. Its material shows excellent stability in the aluminium liquid temperature range of 680-750℃, and its thermal expansion coefficient is close to that of the aluminium liquid, avoiding the risk of rupture caused by sudden temperature changes. More importantly, the surface-treated glass fiber can effectively resist the erosion of aluminium liquid

Essential part for quality metal casting

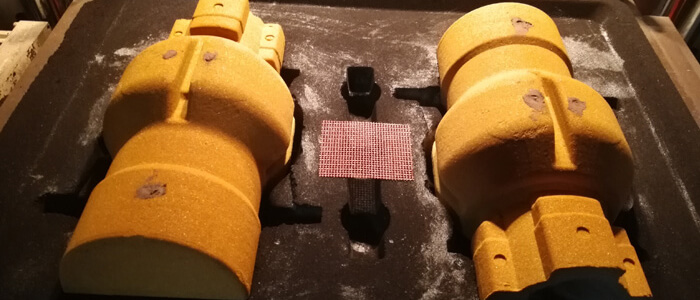

Fiberglass mesh filter play a crucial role in the metal casting process, effectively purifying the metal melt by removing impurities such as bubbles, slag inclusions, and oxides, significantly reducing defects such as porosity and sand holes in castings. At the same time, it can also enhance the mechanical properties of castings, improve hardness, bending strength, and processing performance, making the metal structure more uniform and dense. In addition, cast filter screens have a wide range of applicability and can be optimized for different metals such as cast iron, cast steel, aluminium alloys, etc. They also support customization of different mesh sizes to meet diverse casting process requirements, making them an important tool for improving casting quality and production efficiency.

Key process of temperature adaptation

For the special needs of aluminium casting, before being put into use, the filter must be preheated.This process eliminates the risk of thermal stress cracks and enables the filter to withstand sudden impacts of aluminium liquid. Actual tests show that the service life of the mesh filter that has been preheated in a standardized manner is more than 3 times longer than that of the sample that is directly put into aluminium liquid.

Detailed calculation of cost-effectiveness

Fiberglass mesh filter have significant price advantages in the foundry industry. Compared with traditional ceramic, their raw material costs are lower and their production processes are simpler, which greatly reduces procurement costs. At the same time, glass fiber filters are light in weight, easy to install, and can adapt to different production needs. Whether it is a standard model or a high-end customized model, it can provide higher cost performance while ensuring the filtering effect. For foundry companies that pursue cost reduction and efficiency improvement, glass fiber filters have become a more competitive choice due to their excellent economy and practicality.

Today, It is not only a simple filter medium, but also a precise control device that connects the smelting process and casting quality. With the expansion of the application field of aluminium alloy, this filter that combines traditional materials and modern technology will continue to create visible value enhancement for the foundry industry.