Introduction:

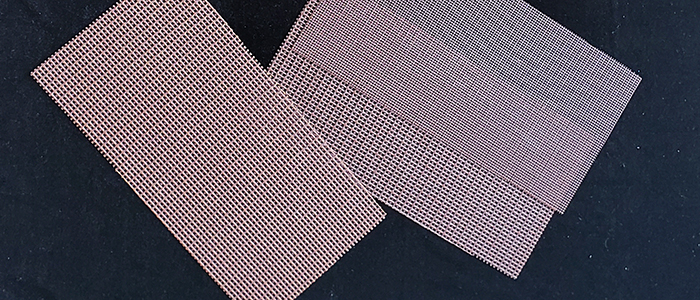

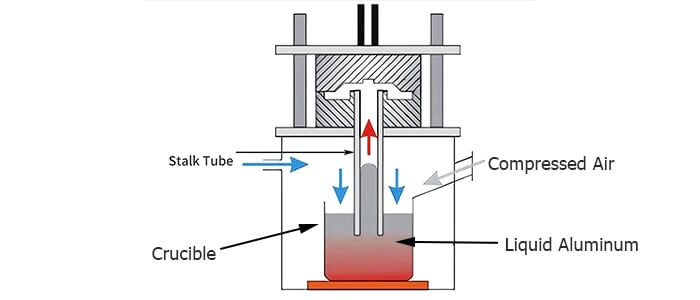

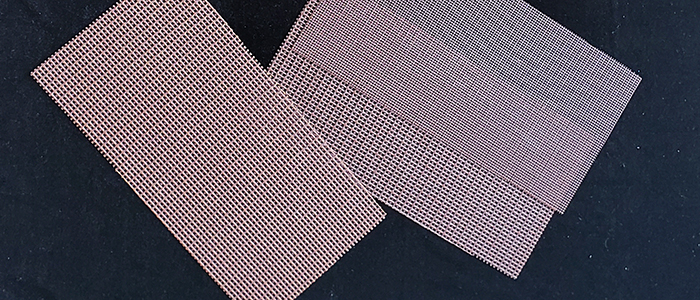

The global export trade market for casting fiberglass mesh filters is anticipated to experience notable developments in the upcoming year. Fiberglass mesh filters play a critical role in the metal casting industry, providing a reliable solution for filtering molten metal and improving the overall casting process. As industries continue to evolve, placing an increased emphasis on precision, efficiency, and sustainability, the demand for high-quality mesh filters is expected to grow. This essay explores the key factors influencing the export trade market for casting fiberglass mesh filters in the next year and outlines potential opportunities and challenges on the horizon.

Market Trends and Dynamics of Fiberglass Mesh Filters:

The casting industry worldwide is witnessing a growing demand for advanced and efficient casting processes. Fiberglass mesh filters have become an integral component of these processes, ensuring the removal of impurities and enhancing the quality of the cast metal. One significant trend in the fiberglass mesh filter market is the continuous innovation in filter design and materials to meet the evolving requirements of the casting industry. Manufacturers are focusing on developing filters that offer improved filtration efficiency, longer lifespan, and compatibility with a wide range of casting alloys.

The adoption of mesh filters is also being driven by their non-reactive nature, corrosion resistance, and ability to withstand high temperatures. As foundries and casting facilities seek to optimize their operations, mesh filters have emerged as a preferred choice for their reliability and cost-effectiveness.

Regional Outlook of Fiberglass Mesh Filters:

The export trade market for casting fiberglass mesh filters is influenced by regional dynamics, with different parts of the world exhibiting varying levels of demand and market preferences. Growing economies with expanding manufacturing sectors are likely to contribute significantly to the demand for mesh filters. Developed markets, on the other hand, may see an increased focus on specialized and advanced filtration solutions.

Asia-Pacific is expected to be a key player in the export trade market for casting filters. Countries such as China, India, and South Korea, with their robust manufacturing activities, are likely to drive substantial demand. North America and Europe, with their emphasis on technological innovation and adherence to environmental standards, are expected to maintain a steady market for high-quality fiberglass filter mesh.

Opportunities and Challenges:

The next year presents both opportunities and challenges for the export trade market of casting fiberglass mesh filters. The rising demand for advanced casting processes and the increasing awareness of the importance of high-quality filtration in metal casting create favorable conditions for filter manufacturers. Moreover, as industries across the globe focus on sustainability, the development and export of environmentally friendly mesh filters present significant opportunities.

However, challenges such as fierce global competition, fluctuations in raw material prices, and the need for compliance with stringent industry standards may pose obstacles for market participants. External factors such as trade regulations, geopolitical events, and economic conditions could also impact the global export landscape for filter mesh.

Conclusion:

In conclusion, the export trade market for casting fiberglass mesh filters in the coming year is poised for growth, driven by advancements in technology, regional demand, and industry trends. Manufacturers that prioritize innovation, quality, and adaptability to diverse casting processes are likely to thrive in this dynamic market. While challenges exist, the overall outlook remains positive, presenting opportunities for expansion and success in the global fiberglass mesh filter market.